In recent years, the automotive sector has witnessed a significant transformation towards sustainable manufacturing practices. As I delve into the evolving landscape of the industry, it’s clear that the focus on sustainability is no longer just a trend but a necessity for the future. Manufacturers are increasingly embracing eco-friendly processes and materials to reduce their environmental footprint and meet the growing demand for greener solutions.

In this article, I’ll explore the key drivers behind this shift towards sustainable manufacturing in the automotive sector and the impact it has on the industry as a whole. From innovative technologies to stringent regulations, the push for sustainability is reshaping how cars are designed, produced, and recycled. Join me on this journey to uncover the challenges, opportunities, and implications of this transformative movement towards a more environmentally conscious automotive industry.

Understanding Sustainable Manufacturing in the Automotive Sector

What Is Sustainable Manufacturing?

Sustainable manufacturing focuses on producing goods using processes that are environmentally friendly, socially responsible, and economically viable. In the automotive sector, this means implementing practices that minimize waste, reduce energy consumption, and limit emissions throughout the entire supply chain. It involves using renewable resources, recycling materials, and adopting sustainable technologies to create a more efficient and eco-conscious manufacturing process.

Why It Matters for the Automotive Industry

Sustainable manufacturing is crucial for the automotive industry as it helps reduce its environmental footprint, improve operational efficiency, and meet the growing demand for eco-friendly vehicles. By embracing sustainable practices, automakers can lower production costs, enhance their brand reputation, and comply with stringent regulations aimed at reducing greenhouse gas emissions and promoting sustainability. Transitioning towards sustainable manufacturing not only benefits the environment but also ensures long-term viability and competitiveness in the evolving automotive market.

Key Trends Driving the Shift Towards Sustainability

Technological Innovations

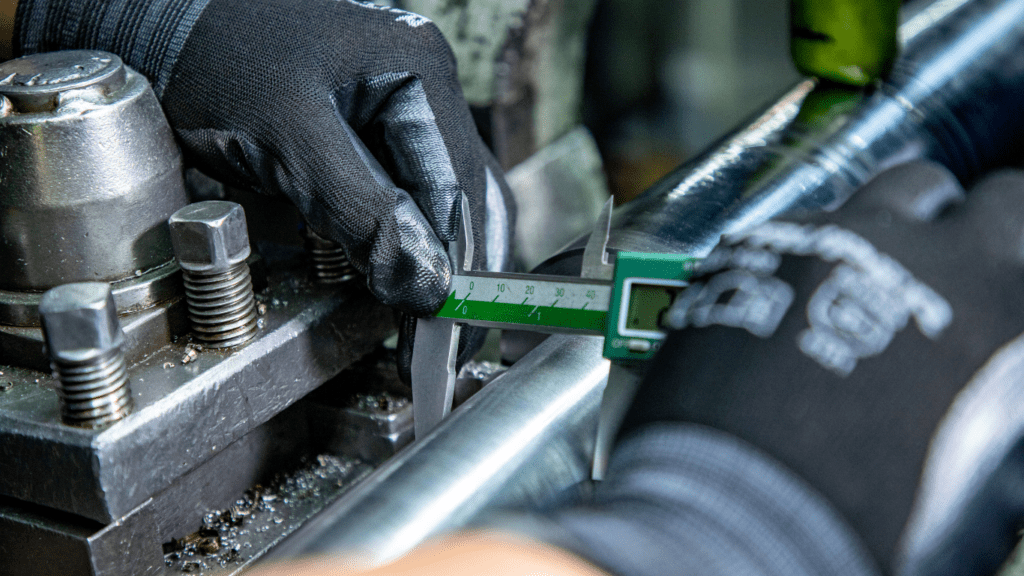

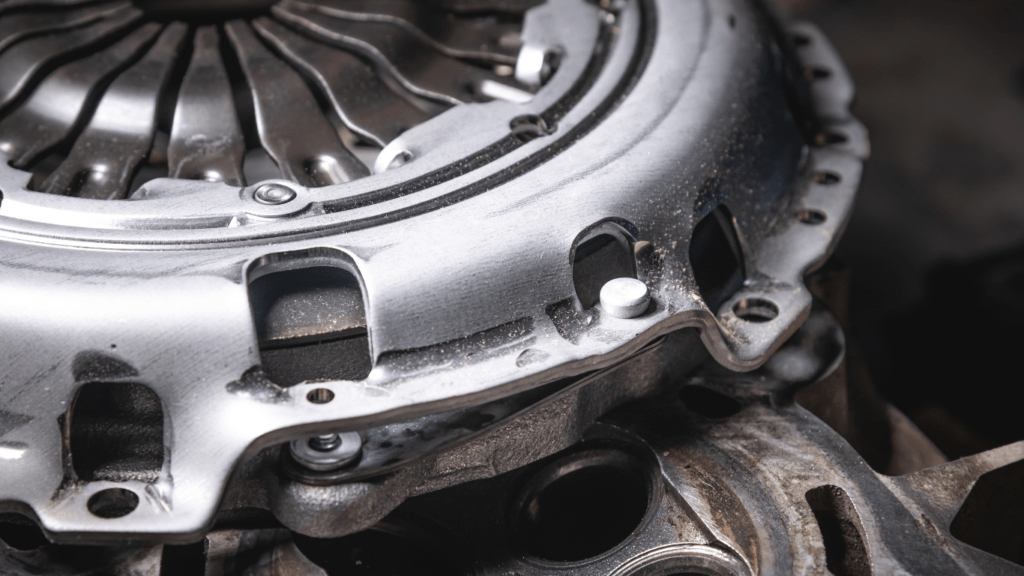

In the realm of sustainable manufacturing in the automotive sector, technological innovations play a pivotal role in driving the shift towards eco-friendly practices. Advancements in materials science have led to the development of lightweight yet highly durable materials that enhance vehicle efficiency while reducing fuel consumption. Additionally, the integration of automation and artificial intelligence in production processes improves precision, reduces waste, and optimizes energy usage. For instance, the use of 3D printing for manufacturing components allows for customization, leading to reduced material wastage. These technological advancements not only bolster environmental sustainability but also contribute to cost savings and operational efficiency for automotive manufacturers.

Regulatory Pressures and Standards

Regulatory pressures and stringent industry standards are significant drivers propelling the automotive sector towards sustainability. Government regulations mandating lower emissions and fuel efficiency targets have compelled automakers to adopt greener practices throughout their operations. Compliance with these regulations not only avoids penalties but also enhances brand reputation by showcasing a commitment to environmental stewardship. Moreover, certifications such as ISO 14001 for environmental management systems and the adoption of sustainability frameworks like the Global Reporting Initiative (GRI) reinforce the importance of sustainable manufacturing practices in the automotive industry. By adhering to these standards, manufacturers ensure transparency, accountability, and alignment with global sustainability goals.

Challenges in Sustainable Automotive Manufacturing

In sustainable automotive manufacturing, several challenges must be addressed to fully embrace eco-friendly practices without compromising efficiency or profitability.

Cost Implications

Reducing the environmental impact of manufacturing processes often comes with initial cost implications, as investing in eco-friendly technologies or materials may require significant capital outlay. While these upfront costs can be a barrier for some manufacturers, the long-term benefits, such as lower operational expenses and enhanced brand reputation, often outweigh the initial investments. Therefore, managing cost implications effectively and strategically is essential for sustainable manufacturing in the automotive sector.

Supply Chain Complexity

The shift towards sustainable automotive manufacturing introduces complexities in the supply chain, requiring closer collaboration with suppliers to ensure the sourcing of environmentally friendly materials and components. From tracking the origins of raw materials to verifying sustainable practices throughout the supply chain, managing this complexity is crucial for maintaining transparency and aligning with sustainability goals. Embracing sustainable practices throughout the supply chain not only enhances environmental stewardship but also fosters a more resilient and responsive automotive manufacturing ecosystem.

Case Studies of Sustainability in Action

As I explore sustainable manufacturing practices in the automotive industry, it’s essential to highlight the practical implementations driving this transformative shift. Let’s delve into some compelling case studies that showcase sustainability in action in the automotive sector.

Leading Automakers and Their Green Initiatives

- Toyota: A pioneer in sustainable manufacturing, Toyota has adopted various eco-friendly practices across its production processes. Implementing lean manufacturing techniques, recycling materials, and optimizing energy usage, Toyota has significantly reduced its environmental footprint while enhancing operational efficiency.

- Tesla: Renowned for its electric vehicles, Tesla has revolutionized the automotive industry by prioritizing sustainability. From utilizing renewable energy sources for production to promoting a circular economy approach for battery recycling, Tesla sets a high standard for green initiatives in the sector.

- BMW: Committed to sustainability, BMW focuses on integrating renewable energy into its manufacturing plants and supply chain. Embracing transparency, BMW emphasizes the use of recycled materials and invests in innovative technologies to minimize waste generation throughout its operations.

- Enhanced Brand Image: Adopting sustainable practices elevates an automaker’s brand image, appealing to environmentally conscious consumers. By demonstrating a commitment to eco-friendly initiatives, companies can attract a wider customer base and strengthen brand loyalty.

- Competitive Advantage: Sustainability is becoming a key differentiator in the automotive market. Companies that prioritize sustainable manufacturing gain a competitive edge by meeting consumer expectations, complying with regulations, and adapting to evolving market trends.

- Long-Term Viability: Investing in sustainable practices ensures the long-term viability of automakers in a rapidly changing industry. By reducing environmental impact, optimizing resource utilization, and mitigating risks, companies secure their position in a sustainable future.

These case studies and insights highlight the significant role of sustainability in shaping the automotive sector, driving innovation, and fostering a greener, more resilient industry landscape.