As someone passionate about environmental sustainability, I’ve delved into the intricate web of how battery production and disposal affect our planet. The ubiquity of batteries in our daily lives often masks the hidden costs they impose on the environment. From the mining of raw materials to the disposal of used batteries, each step in the lifecycle leaves a distinct ecological footprint.

In this article, I’ll shed light on the environmental ramifications of battery manufacturing and disposal processes. It’s crucial to understand the full scope of these impacts to make informed decisions about our energy consumption habits. By exploring the lifecycle of batteries, we can uncover ways to minimize their environmental consequences and pave the way for a more sustainable future.

Exploring the Environmental Impact of Battery Production

In understanding the environmental impact of battery production, it’s crucial to examine the key materials used and their extraction process, along with the energy consumption involved in battery manufacturing.

Key Materials and Their Extraction

Lithium, cobalt, nickel, and other materials essential for battery production are often mined in a manner that can harm the environment. The extraction of these resources can lead to deforestation, soil erosion, and water pollution, impacting ecosystems and local communities. It’s imperative to consider sustainable sourcing practices and the recycling of materials to mitigate these environmental consequences.

Energy Consumption in Battery Manufacturing

Battery manufacturing is an energy-intensive process, requiring significant electricity usage for the production of cells and packs. The high energy demand contributes to carbon emissions and air pollution, emphasizing the importance of adopting renewable energy sources in manufacturing facilities. Improving energy efficiency and transitioning to cleaner energy sources can help reduce the environmental footprint of battery production.

Disposal and Recycling Challenges

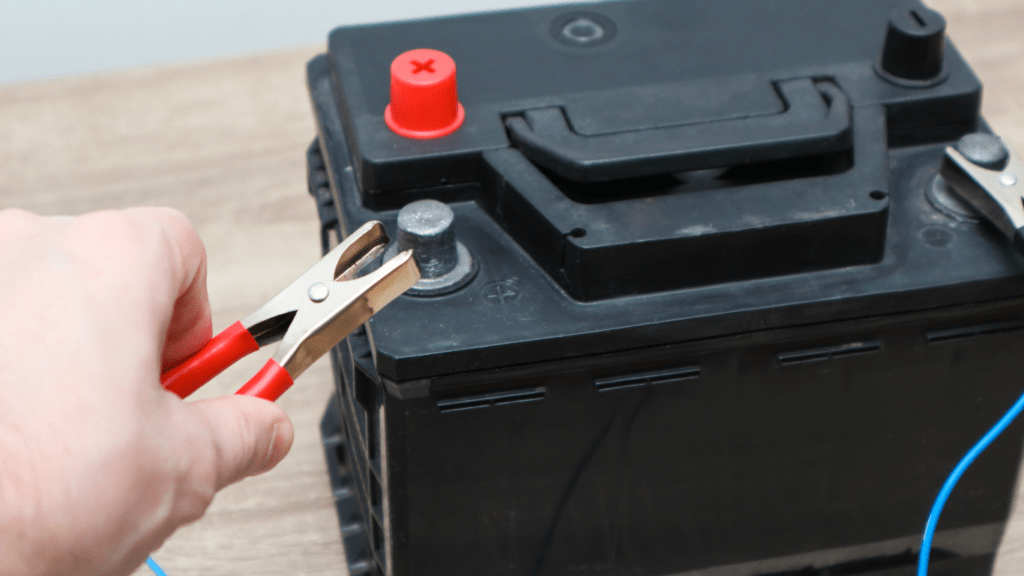

When addressing the disposal and recycling of batteries, it’s crucial to understand the environmental hazards associated with improper disposal and the advancements made in battery recycling technologies.

Environmental Hazards of Improper Disposal

Improper disposal of batteries poses significant environmental risks due to the potential leakage of harmful chemicals into soil and water sources. Substances like lead, cadmium, and other heavy metals found in batteries can contaminate the environment, posing threats to ecosystems and human health. It’s vital to implement proper disposal methods to prevent these toxins from seeping into the environment.

Advances in Battery Recycling Technologies

Recent advancements in battery recycling technologies offer promising solutions to mitigate the environmental impact of battery disposal. Innovative processes now enable the recovery and reuse of valuable materials such as lithium, cobalt, and nickel from spent batteries. By efficiently recycling these components, we can reduce the need for raw material extraction, lowering energy consumption and minimizing environmental damage.

Solutions and Innovations in Battery Production

To address the environmental impact of battery production, it’s crucial to focus on solutions and innovations that can mitigate these effects. Implementing sustainable practices and embracing innovative technologies play a vital role in reducing the ecological footprint of batteries throughout their lifecycle.

- Reducing the Carbon Footprint

One key aspect of improving the environmental sustainability of battery production is reducing the carbon footprint associated with manufacturing processes. By optimizing energy efficiency, adopting renewable energy sources, and implementing carbon capture technologies, manufacturers can significantly decrease the greenhouse gas emissions generated during battery production. These initiatives not only help combat climate change but also promote a greener and more sustainable approach to battery manufacturing. - Sustainable Material Alternatives

Exploring sustainable material alternatives is another promising avenue for enhancing the environmental sustainability of battery production. Researchers and manufacturers are increasingly focusing on finding substitutes for traditional battery materials like cobalt and nickel to reduce dependence on mined resources with high environmental costs. By experimenting with materials that are more abundant, environmentally friendly, and ethically sourced, such as iron or sodium, the industry can move towards a more sustainable and eco-conscious approach to battery production.

Regulatory and Policy Framework

When considering the environmental impact of battery production and disposal, it’s crucial to understand the regulatory and policy frameworks in place to address these issues.

Global Environmental Policies on Batteries

Global environmental policies play a significant role in shaping the practices and standards surrounding battery production and disposal. Organizations like the International Energy Agency (IEA) and the United Nations Environment Programme (UNEP) have been instrumental in developing guidelines to regulate the environmental impact of batteries. These policies often focus on reducing greenhouse gas emissions, promoting sustainable practices, and encouraging the recycling and proper disposal of batteries to minimize their environmental footprint. Adhering to these global policies is key to ensuring a more environmentally friendly approach to battery manufacturing and disposal on a global scale.

Future Directions in Environmental Regulations

As technology advances and environmental awareness grows, the future of environmental regulations in the battery industry is likely to become more stringent. Governments and regulatory bodies around the world are increasingly emphasizing the importance of sustainable practices and enforcing stricter regulations to mitigate the environmental impact of batteries. This includes initiatives to promote research and development of eco-friendly materials, improve recycling processes, and reduce carbon emissions throughout the battery lifecycle. Keeping abreast of these evolving regulations and aligning with future environmental standards will be essential for manufacturers to stay compliant and contribute to a more sustainable future.