In today’s fast-paced world, technological advancements have revolutionized every industry, and automotive production is no exception. As an automotive enthusiast, I’ve witnessed firsthand how cutting-edge technologies have transformed the way vehicles are manufactured. From robotics and automation to artificial intelligence and 3D printing, these innovations have significantly enhanced efficiency, precision, and sustainability in the production process.

In this article, I’ll delve into the profound impact that technological advancements have had on automotive production. As I explore key advancements such as smart manufacturing systems and Internet of Things (IoT) integration, I’ll highlight the benefits they bring to the industry, including improved quality control, streamlined operations, and accelerated innovation. Join me on this journey to discover how technology continues to shape the future of automotive manufacturing.

Evolution of Automotive Production

Automotive production has evolved significantly over the years, driven by technological advancements that have transformed traditional processes. From Assembly Lines to Automation and Key Technological Milestones, the industry has witnessed a remarkable shift towards innovation and efficiency.

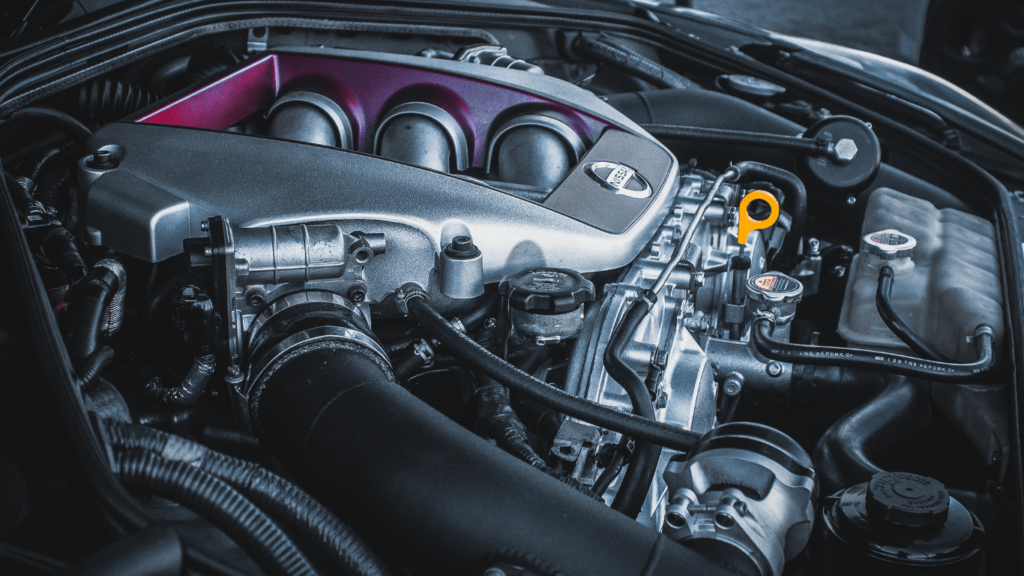

From Assembly Lines to Automation

I’ll delve into how automotive production has transitioned from the manual labor-intensive assembly lines to sophisticated automated systems that optimize production processes. This shift has led to increased productivity, reduced costs, and enhanced precision in manufacturing vehicles.

Key Technological Milestones

I’ll explore the significant technological milestones that have shaped automotive production, including robotics, AI integration, 3D printing, and advanced analytics. These advancements have revolutionized the industry by improving production speed, product quality, and overall operational efficiency.

Role of Artificial Intelligence in Modern Vehicles

AI in Production Processes

In today’s automotive industry, AI plays a crucial role in optimizing production processes. It automates repetitive tasks, accelerates decision-making, and enhances overall efficiency. AI algorithms analyze data in real-time, allowing for predictive maintenance to minimize downtime and prevent unexpected failures. For example, AI-powered robots are used in assembling vehicles, ensuring precision and speed that surpass human capabilities. By seamlessly integrating AI into production processes, manufacturers can achieve higher levels of productivity and quality control.

AI in Vehicle Functionality

Artificial Intelligence has also revolutionized vehicle functionality, enhancing safety, convenience, and driving experience. Advanced driver-assistance systems (ADAS) rely on AI to interpret sensor data, enabling features like lane-keeping assistance, adaptive cruise control, and automatic emergency braking. AI algorithms continuously learn and adapt to improve performance, leading to enhanced safety standards in modern vehicles. Moreover, AI-driven infotainment systems personalize the driving experience by understanding driver preferences and providing real-time navigation assistance, making journeys more enjoyable and efficient.

Advancements in Materials and Manufacturing Techniques

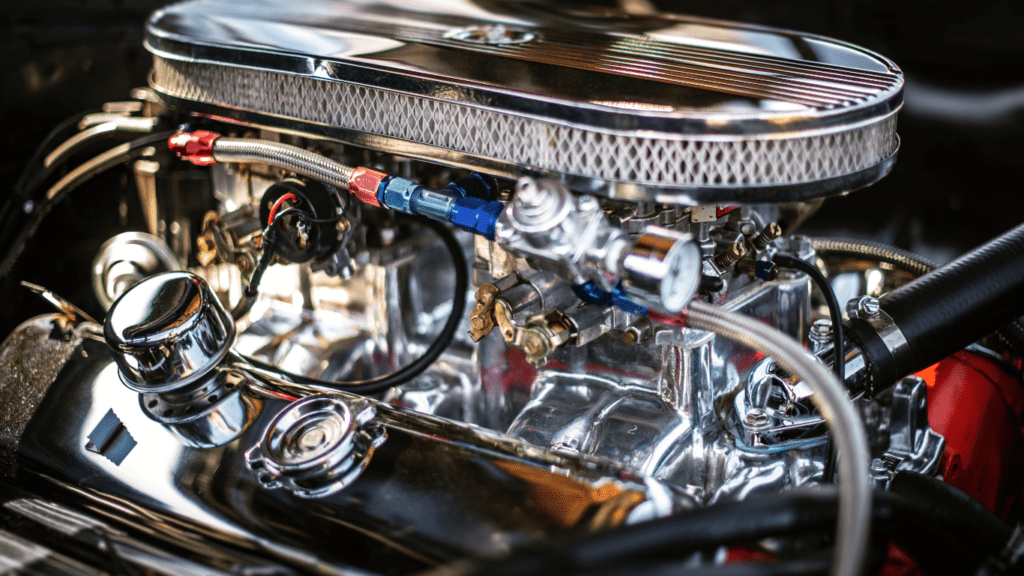

As technologies advance, the automotive industry continues to witness significant developments in materials and manufacturing techniques, revolutionizing the way vehicles are designed and built.

- Lightweight Materials and Composites

I’ll delve into how lightweight materials and composites have transformed automotive manufacturing. Lightweight materials like carbon fiber, aluminum, and high-strength steel are increasingly used in vehicle construction. These materials offer improved fuel efficiency, better performance, and enhanced durability. By reducing the overall weight of vehicles, manufacturers can achieve greater energy efficiency and lower emissions, aligning with the industry’s push towards sustainability. - Advanced Fabrication Technologies

I’ll now discuss the impact of advanced fabrication technologies on automotive production. Techniques such as additive manufacturing (3D printing), laser cutting, and automated assembly systems have streamlined production processes, leading to higher precision, faster turnaround times, and increased customization capabilities. These technologies enable manufacturers to create complex components with reduced waste, driving efficiency and cost-effectiveness in the production line.

Environmental Implications of Technological Advances

The advancement of technology in automotive production has not only revolutionized efficiency and precision but also significantly impacted the environmental sustainability of the industry.

Reduction in Carbon Footprint

Incorporating technological advancements like robotics, AI integration, and advanced analytics has led to a substantial reduction in the automotive industry’s carbon footprint. Automation of manufacturing processes has minimized waste and optimized energy consumption, mitigating the environmental impact of vehicle production.

Energy-Efficient Manufacturing Practices

The implementation of energy-efficient manufacturing practices, facilitated by technological innovations, has further enhanced the sustainability of automotive production. From the utilization of lightweight materials like carbon fiber to the adoption of advanced fabrication technologies such as 3D printing, the industry is moving towards greener and more energy-conscious manufacturing processes. These practices not only improve energy efficiency but also contribute to reducing greenhouse gas emissions and promoting environmental conservation in automotive manufacturing.